Overview

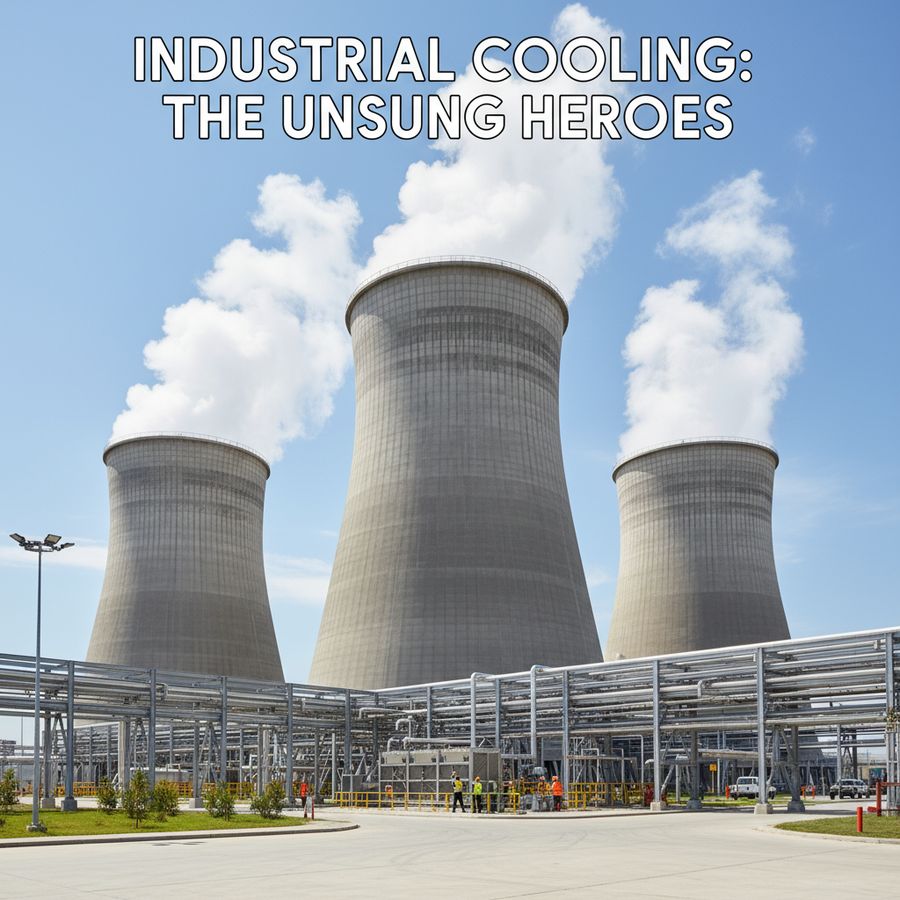

Industrial cooling towers play a vital role in maintaining optimal temperatures within large-scale industrial processes, ensuring equipment efficiency and operational stability. These towers are engineered systems designed to expel the heat generated by machines or manufacturing processes into the atmosphere, primarily through the evaporation of water. Their significance spans multiple industries, from chemical manufacturing to plastics, packaging, and beyond.

At their core, cooling towers are indispensable components of industrial cooling infrastructure, serving to protect machinery from overheating and to improve energy management across production lines. As industries evolve and environmental regulations tighten, the demand for advanced cooling tower designs and operational best practices has never been greater. This blog post delves deep into the fundamentals, design considerations, energy efficiency approaches, and maintenance practices essential for maximizing the performance of cooling towers.

Given the complexity and scale of industrial facilities today, selecting and maintaining the right cooling tower system is a strategic decision. It impacts not only operational costs but also environmental impact and system longevity. In this context, understanding the core principles behind cooling towers and the latest innovations in design best practices and energy efficiency can significantly benefit facility managers and engineers.

“Optimizing cooling tower operations is crucial for sustainable industrial production, enhancing energy savings while safeguarding machinery.”

Cooling Tower Fundamentals

Cooling towers operate by transferring heat from hot water discharged from industrial processes to the atmosphere, predominantly using evaporation. This process cools the water, which then recirculates back into the system to absorb more heat. The effectiveness of this heat exchange hinges on the design and operation of the cooling tower’s components, including fill media, fans, and water distribution systems.

The two main types of cooling towers used in industry are wet cooling towers and dry cooling towers. Wet cooling towers rely on evaporative cooling, making them highly efficient for removing heat but requiring careful water treatment to prevent scaling and biological growth. Dry cooling towers, conversely, use air to cool the water without evaporation, useful in water-scarce environments but generally less efficient.

The cooling process involves hot water entering the tower at the top, where it is distributed over fill materials that increase the surface area for heat transfer. Simultaneously, air is drawn or forced upward through the tower, either by natural draft or fans, facilitating evaporation and heat dissipation. The cooled water collects at the basin for reuse.

“Understanding the thermodynamics behind cooling towers ensures better control over thermal loads and system efficiency.”

Critical factors influencing performance include ambient temperature, humidity, and airflow rates. Proper design and operation balance these elements to optimize cooling performance while minimizing energy consumption and water usage.

Design Considerations

The design of an industrial cooling tower must be approached with precision, focusing on both functional requirements and environmental conditions. Key design best practices involve tailoring the system to the specific heat load, water quality, available space, and climate conditions.

One of the foremost design considerations is selecting the appropriate tower type—whether crossflow, counterflow, or induced draft—each offering distinct advantages depending on airflow patterns and maintenance accessibility. For instance, induced draft towers with fans at the top are known for their high thermal efficiency and reduced drift losses.

An effective cooling tower design also incorporates:

-

High-quality fill media to maximize heat transfer surface area.

-

Robust water distribution systems ensuring even water coverage.

-

Corrosion-resistant materials to extend lifespan and reduce downtime.

-

Sound attenuation features for noise-sensitive environments.

Moreover, environmental compliance is critical. Designers must consider emissions, water consumption, and potential chemical discharges. Integrating energy-efficient fans and variable speed drives can substantially reduce operational costs.

Frimec, with over 55 years of expertise in industrial refrigeration, emphasizes tailor-made solutions that align with these best practices, ensuring reliability and sustainability in industrial temperature control.

Energy Efficiency Techniques

Energy efficiency in industrial cooling towers is paramount for reducing operational costs and environmental footprint. Implementing advanced techniques can significantly enhance system performance while conserving resources.

Some of the most effective energy efficiency strategies include:

-

Variable Frequency Drives (VFDs): Adjust fan speed based on real-time cooling demand, minimizing unnecessary energy use.

-

Optimized Water Flow Control: Using sensors and automated valves to regulate water distribution and flow rates precisely.

-

Advanced Fill Media: Utilizing materials that improve heat transfer efficiency reduces the required airflow and energy consumption.

-

Free Cooling Integration: Leveraging ambient conditions during cooler periods to reduce mechanical cooling loads.

In addition, regular system audits and monitoring allow operators to identify inefficiencies early, leading to timely interventions. The use of high-efficiency motors and fan blades designed for aerodynamic performance also contributes to lowering energy consumption.

“Investing in energy-efficient cooling tower technologies not only cuts costs but also supports environmental stewardship in industrial operations.”

By adopting these techniques, industries can achieve a balance between high operational performance and sustainability goals, ultimately enhancing their competitive edge.

Water Treatment Importance

Proper water treatment is essential for maintaining the longevity and efficiency of cooling towers. Untreated water can lead to scaling, corrosion, biological growth, and fouling, which degrade performance and increase maintenance costs.

Effective water treatment programs typically involve:

-

Scale Inhibitors: Chemicals that prevent mineral deposits from forming on heat exchange surfaces.

-

Corrosion Inhibitors: Additives that protect metal components from oxidation and degradation.

-

Biocides: Agents used to control microbial growth, including algae and bacteria, which can clog systems and pose health risks.

-

pH Control: Maintaining optimal pH levels to minimize corrosive or scaling tendencies.

Water quality monitoring is crucial and should be conducted regularly to adjust treatment protocols accordingly. Implementing automated dosing systems can improve precision and reduce chemical usage.

“Neglecting water treatment can compromise cooling tower efficiency and lead to costly repairs or system downtime.”

Integrating water treatment with the overall operational strategy ensures sustainable use of water resources, aligns with environmental regulations, and extends the equipment’s service life.

Common Industrial Uses

Cooling towers are indispensable across a diverse range of industries where heat dissipation is critical. Their adaptability and efficiency make them a preferred solution in sectors such as:

-

Chemical Industry: Cooling towers regulate temperatures in reactors, condensers, and other heat-intensive processes.

-

Plastic Manufacturing: They cool molds and machinery to maintain production quality.

-

Packaging and Printing: Temperature control ensures product integrity and machinery reliability.

-

Metalworking and Diecasting: Cooling towers dissipate heat from high-temperature processes like casting and forging.

-

Food and Beverage Processing: Temperature regulation is essential for hygiene and product consistency.

Each application demands customized cooling solutions tailored to specific thermal loads, environmental conditions, and operational priorities. Frimec’s extensive experience in providing tailor-made industrial refrigeration and temperature control solutions highlights their commitment to excellence and innovation across these sectors.

By understanding the unique requirements of each industry, cooling towers can be optimized to deliver reliable, cost-effective cooling that supports uninterrupted production and quality assurance.

Maintenance Guidelines

Adhering to rigorous maintenance guidelines is crucial for the sustained performance and reliability of industrial cooling towers. A comprehensive maintenance program minimizes downtime, extends equipment lifespan, and ensures energy efficiency remains high.

Key maintenance practices include:

-

Regular Inspection: Check for corrosion, leaks, fan operation, and structural integrity.

-

Cleaning: Remove dirt, biological growth, and scale deposits from fill media and basins.

-

Water Treatment Monitoring: Consistently test water quality and adjust chemical treatments as needed.

-

Lubrication: Maintain fan motors and bearings to reduce wear and energy loss.

-

Component Replacement: Timely replacement of worn parts such as nozzles, fans, and pumps.

Preventive maintenance is preferred over reactive repairs, as it prevents costly breakdowns and ensures steady operation. Utilizing digital monitoring tools can help track system performance in real time, allowing for predictive maintenance interventions.

“A proactive maintenance approach is key to maximizing cooling tower efficiency and safeguarding industrial processes.”

Partnering with experienced service providers like Frimec guarantees expert support from system design through to ongoing maintenance, ensuring your cooling towers perform at their best.

Conclusion

Industrial cooling towers remain a cornerstone of effective temperature control in modern manufacturing and processing environments. Understanding their fundamentals, embracing design best practices, and implementing robust energy efficiency and water treatment strategies are essential for maximizing performance and sustainability.

By focusing on customized designs that meet specific industrial requirements and ensuring consistent maintenance, businesses can realize considerable operational savings while minimizing their environmental footprint. The expertise and innovation showcased by industry leaders like Frimec offer a dependable route for companies in search of advanced, eco-friendly cooling solutions.

“Investing in well-designed and efficiently operated cooling towers is an investment in the longevity, sustainability, and success of your industrial operations.”

As industries continue to evolve, staying informed on the latest advancements and best practices in cooling tower technology will remain critical for maintaining competitive advantage and operational excellence.