Overview

Temperature control is a critical factor in the plastic manufacturing industry. Maintaining precise and consistent temperatures throughout the various stages of plastic processing directly influences product quality, production efficiency, and operational costs. As plastics are sensitive materials that react to thermal variations, controlling the temperature during molding, extrusion, and cooling phases ensures that the final products meet stringent quality standards.

In industrial cooling contexts, temperature control systems are designed to manage heat generated by plastic processing equipment and maintain optimal conditions for forming and shaping plastics. This control reduces defects such as warping, internal stresses, and surface imperfections, which can arise from uneven or uncontrolled cooling.

Industrial cooling technologies, including chillers, cooling towers, and thermoregulation units, play a vital role in this process by efficiently removing excess heat and stabilizing production temperatures. This results in enhanced product quality and consistency, reduced cycle times, and significant energy savings for manufacturers.

“Effective temperature control is not just a process requirement; it is a strategic advantage that enhances product integrity and operational sustainability in plastic manufacturing.”

With growing environmental concerns and economic pressures, implementing advanced temperature regulation systems in plastic manufacturing has become indispensable. Optimized temperature management supports sustainability goals by minimizing energy consumption while maximizing production output and reliability.

Cooling Challenges in Plastics

The plastic manufacturing industry faces several cooling challenges that can affect the quality and efficiency of production. One of the primary difficulties is managing the rapid and uniform cooling of plastic parts, which is crucial to prevent defects such as shrinkage, warpage, and residual stress.

Plastics typically have low thermal conductivity, making heat transfer during cooling slow and uneven. This can lead to temperature gradients within the molded parts, causing dimensional inaccuracies and mechanical weaknesses. Additionally, fluctuating ambient temperatures and varying production loads further complicate maintaining steady cooling conditions.

Another challenge lies in integrating cooling systems that can adapt to different plastic materials and molding processes, which require diverse temperature ranges and cooling rates. The complexity of molds, the cycle time constraints, and the heat generated by high-speed machinery also demand robust cooling solutions that are both precise and reliable.

Industrial cooling systems must address these challenges by providing consistent temperature control that can be finely tuned to the specific requirements of each manufacturing step. Inadequate cooling not only degrades product quality but also increases energy consumption, leading to higher operational costs and environmental impact.

“Overcoming cooling challenges in plastic manufacturing is essential to achieving high productivity and superior product standards while maintaining energy efficiency.”

Temperature Control Solutions

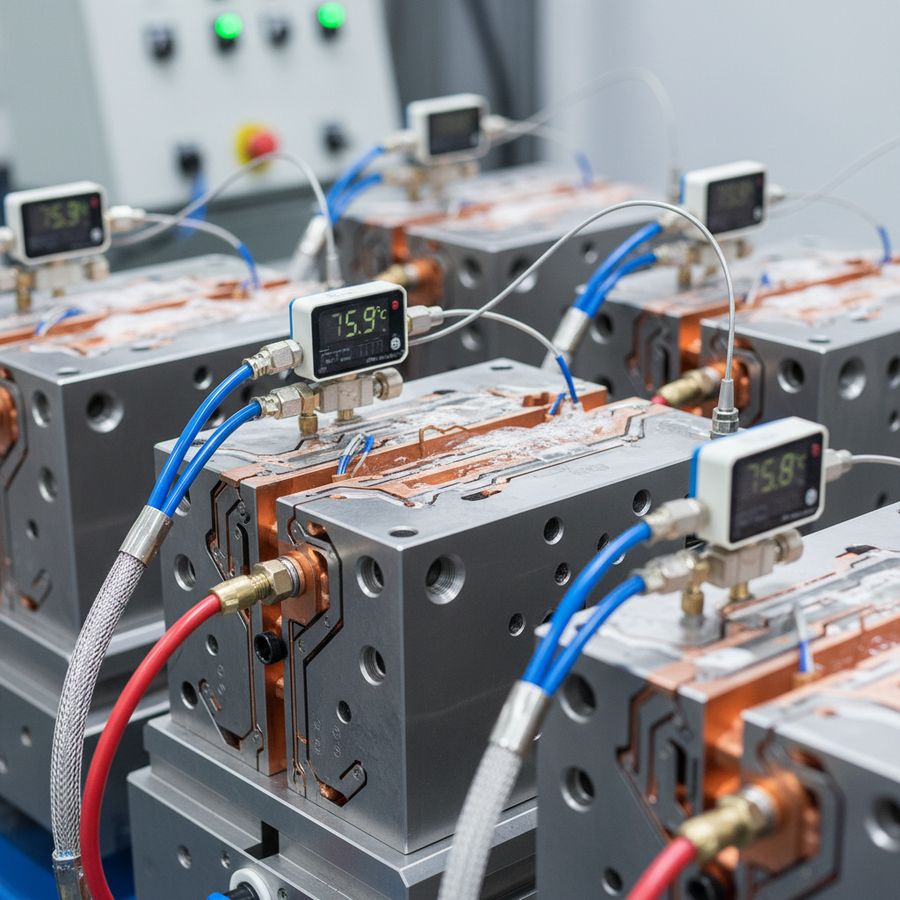

To tackle the complex cooling needs of plastic manufacturing, a variety of advanced temperature control solutions have been developed. These solutions are designed to deliver precise, stable, and efficient temperature regulation throughout the production cycle.

One of the most common solutions is the use of industrial chillers that circulate cooled water or other fluids through molds and machinery, extracting excess heat rapidly and uniformly. These chillers come in various configurations, including air-cooled and water-cooled units, tailored to different plant sizes and cooling capacities.

Thermoregulation units that maintain both heating and cooling functions allow manufacturers to keep molds at exact temperatures, improving cycle times and reducing defects. Technologies such as free cooling, which utilizes ambient temperatures to reduce chiller load, contribute to energy savings and sustainability.

-

Closed-loop cooling systems for precise temperature management

-

Modular chillers for scalability and flexibility

-

Pressure-controlled water temperature regulators to maintain stable flow conditions

-

Integration with automation systems for real-time temperature monitoring and adjustments

Choosing the right temperature control solution depends on factors such as the type of plastic, production volume, mold complexity, and environmental considerations. Partnering with experienced providers who offer tailored systems ensures that manufacturers can optimize their operations and maintain high product quality.

Impact on Product Quality

The role of precise temperature control in enhancing product quality in plastic manufacturing cannot be overstated. Temperature fluctuations during molding and cooling directly affect the physical and mechanical properties of plastic components.

Consistent temperature control helps in achieving uniform material solidification, which minimizes internal stresses and prevents defects like warping, sink marks, and surface blemishes. This leads to higher dimensional accuracy, better surface finish, and improved mechanical strength of the final products.

Moreover, maintaining the correct temperature profiles reduces cycle times by optimizing cooling rates, which not only increases throughput but also ensures repeatability and reliability across production batches. This consistency is vital for industries requiring tight tolerances and high-performance plastic parts.

“Product quality in plastic manufacturing is intrinsically linked to the precision of temperature control throughout the production process.”

Implementing sophisticated temperature control systems also supports compliance with industry standards and customer specifications, thereby enhancing brand reputation and reducing waste due to rejected parts. Ultimately, temperature regulation is a fundamental component of quality assurance in plastic manufacturing.

Energy Efficiency

Energy consumption is a significant operational cost in plastic manufacturing, and effective temperature control can substantially contribute to energy savings. Industrial cooling systems that are optimized for efficiency reduce power usage while maintaining the strict temperature tolerances required for high-quality plastic production.

Modern chillers and thermoregulation units are designed with energy-saving features such as variable speed drives, which adjust compressor and pump speeds based on demand, and free cooling systems that leverage ambient conditions to minimize mechanical cooling. These innovations reduce the carbon footprint of manufacturing facilities.

Energy efficiency is further enhanced by maintaining well-insulated cooling circuits and utilizing advanced control algorithms that prevent overcooling or unnecessary operation of cooling equipment. This not only lowers electricity bills but also extends the lifespan of machinery by reducing wear and tear.

-

Adoption of environmentally friendly refrigerants in chillers

-

Integration of smart sensors for precise temperature feedback

-

Implementation of preventive maintenance programs to ensure optimal system performance

Incorporating efficient temperature control solutions aligns with global sustainability goals, helping manufacturers meet regulatory requirements while achieving cost-effective production. Investing in advanced industrial cooling technologies offers both immediate and long-term economic and environmental benefits.

Case Studies

Several leading plastic manufacturers have reported remarkable improvements by implementing state-of-the-art temperature control and industrial cooling systems. These case studies demonstrate tangible benefits in terms of product quality, energy efficiency, and operational reliability.

For example, a major European plastics producer integrated a modular chiller system with free cooling capability to regulate mold temperatures across multiple production lines. This solution reduced cycle times by 15% and cut energy consumption by 20%, resulting in substantial cost savings and improved product consistency.

Another case involved a manufacturer specializing in high-precision plastic components who adopted pressure-controlled water temperature regulators. This innovation eliminated temperature fluctuations that previously caused warpage and dimensional inaccuracies, enhancing the yield rate and customer satisfaction.

“Customized temperature control solutions have proven to be game-changers for plastic manufacturers committed to quality and sustainability.”

These success stories underscore the importance of selecting tailored cooling and temperature control technologies that address specific production challenges. Collaborating with experienced suppliers who offer comprehensive technical support ensures seamless integration and maximized benefits.

Conclusion

In conclusion, effective temperature control is fundamental to the success of plastic manufacturing. It directly impacts product quality, production efficiency, and energy consumption, making it a cornerstone of modern industrial processes.

By addressing cooling challenges through innovative solutions such as advanced chillers, thermoregulation units, and smart control systems, manufacturers can achieve consistent results that meet stringent quality standards while reducing operational costs. The benefits extend beyond production, contributing to environmental sustainability through significant energy savings.

Industrial cooling and temperature control technologies are evolving rapidly, offering tailored options that align with diverse manufacturing needs. Investing in these systems is not only a strategic decision to enhance competitiveness but also a commitment to sustainable industrial growth.

“Mastering temperature control in plastic manufacturing is key to unlocking superior quality, operational excellence, and environmental responsibility.”

For plastic manufacturers aiming to enhance their cooling strategies, collaborating with experienced providers who grasp the complexities of industrial temperature regulation is crucial. This partnership guarantees the implementation of efficient, dependable, and energy-saving systems that foster long-term success. Learn more about optimizing your cooling solutions here.